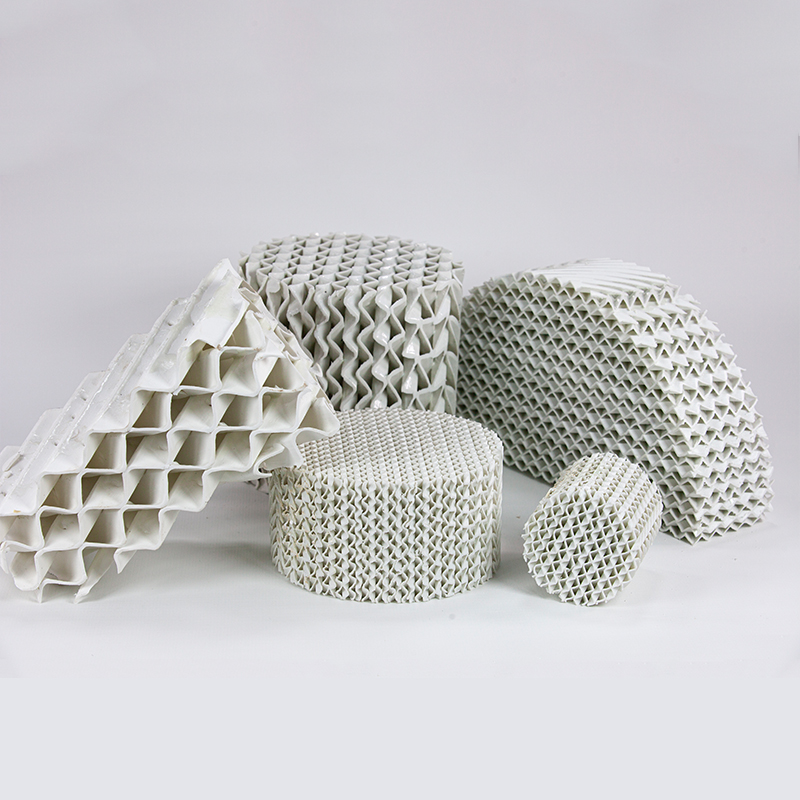

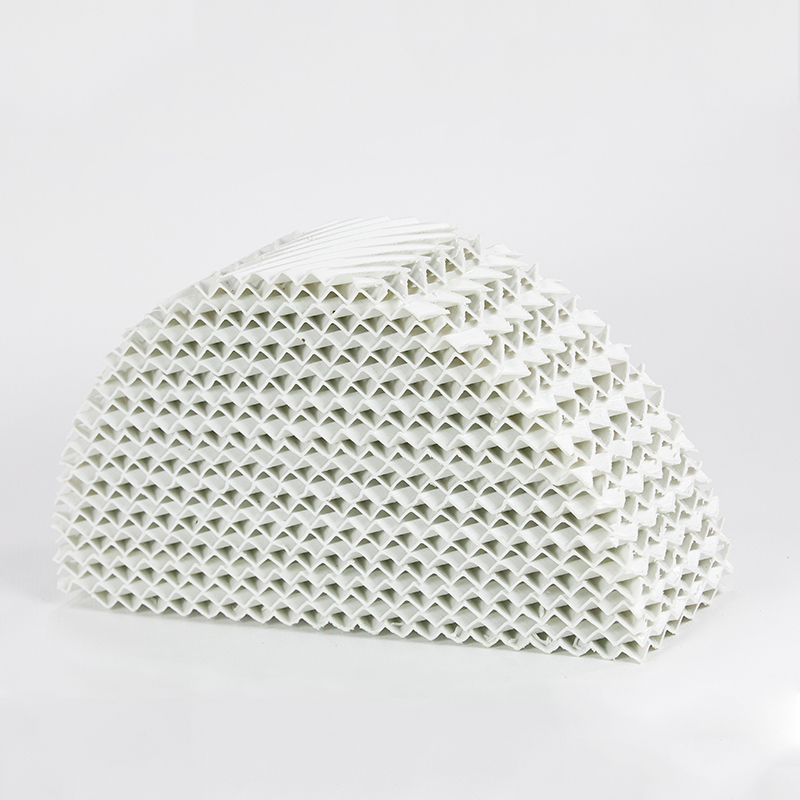

I-Ceramic Structured Packing kunye nohlobo lwe-125Y & 250Y

Ngenxa yesakhiwo esikhethekileyo se-ceramic, ukusebenza kakuhle kwe-hydrophilic, umphezulu wayo unokwenza ifilimu yolwelo olucekeceke kakhulu lwe-airflow esiphithizelayo kunye nemijelo ephazamisayo inokukhuthaza umoya kodwa ingayeki ukuhambelana nomoya we-metal filler unokwenza ukupakishwa kwe-ceramic, kunye nokuxhathisa kwayo ku-corrosion, ukusebenza okuphezulu kokumelana nokushisa kwe-metal filler ayikwazi ukuthelekisa. overheating, aggregation, and coking.Le mveliso yenziwe ngomgangatho ophezulu wekhemikhali porcelain dongwe processing impahla ekrwada kwaye ibe, ukumelana nobushushu obuphezulu kunye noxinzelelo oluphezulu, uzinzo kakuhle imichiza kunye namandla aphezulu, ngumthwalo ofanelekileyo ukuxhasa iintlobo ezahlukeneyo ze-catalysts.

Uhlalutyo lweMichiza

| Ukuqamba | Ixabiso |

| SiO2 | ≥72% |

| Fe2O3 | ≤0.5% |

| CaO | ≤1.0% |

| Al2O3 | ≥23% |

| MgO | ≤1.0% |

| Okunye | 2% |

Impahla Ephathekayo

| Isalathiso | Ixabiso |

| Umxhuzulane okhethekileyo(g/cm3) | 2.5 |

| Ukufunxwa kwamanzi (wt%) | ≤0.5 |

| Ukumelana ne-Acid (wt%) | ≥99.5 |

| Ilahleko ekutshisweni (wt%) | ≤5.0 |

| Max. Ubushushu bokusebenza.(℃) | 800 |

| Amandla okutyumza (Mpa) | ≥130 |

| Ukuqina kukaMoh (Isikali) | ≥7 |

Umhla wobugcisa

| Spec. | Umphezulu othe ngqo (m2/m3) | Ubuninzi bobuninzi (kg/m3) | Umlinganiselo ongekhoyo (%) | Obl. Iengile | Ukuhla koxinzelelo (mm Hg/m) | Theo. Icwecwe (m-1) | Idayamitha yeHydraulic (mm) | Umthwalo wolwelo (m3/m2h) | Max. Factor m/s (Kg/m3)-1 |

| 125Y | 125 | 320 | 90 | 45 | 1.8 | 1.8 | 28 | 0.2-100 | 3.0 |

| 250Y | 250 | 420 | 80 | 45 | 2 | 2.5 | 12 | 0.2-100 | 2.6 |

| 350Y | 350 | 470 | 78 | 45 | 2.5 | 2.8 | 10 | 0.2-100 | 2.5 |

| 450Y | 450 | 520 | 72 | 45 | 4 | 4 | 7 | 0.2-100 | 1.8 |

| 550Y | 550 | 620 | 74 | 45 | 5.5 | 5-6 | 6 | 0.18-100 | 1.4 |

| 700Y | 700 | 650 | 72 | 45 | 6 | 7 | 5 | 0.15-100 | 1.3 |