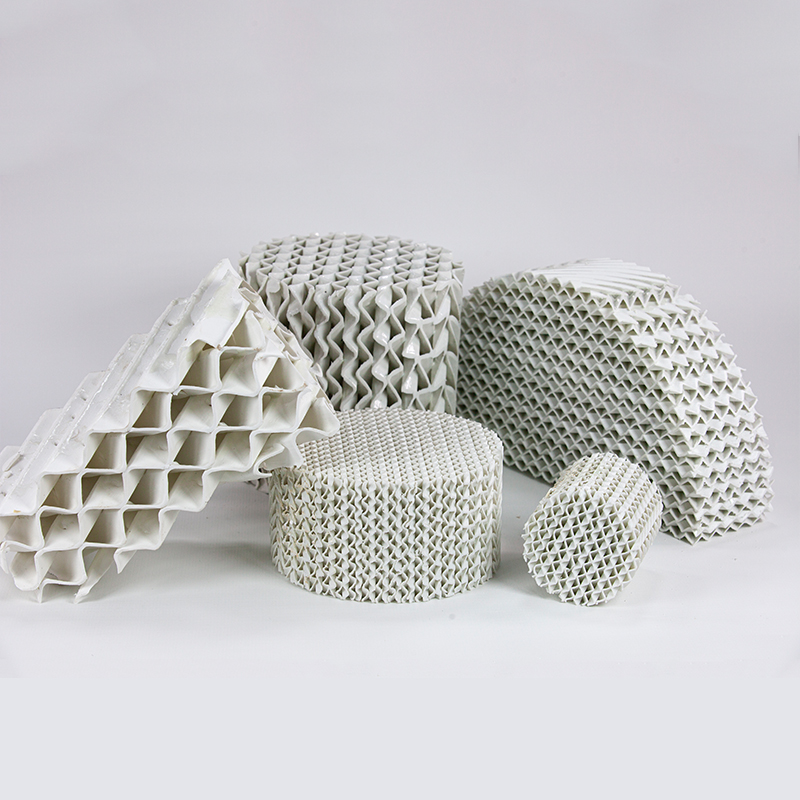

Ukumelana nokushisa kweFactory kudityaniswe neCermaic Light Packing yescrubber Tower

| Ubungakanani | X-01 | X-11 | X-12 | X-13 | X-14 |

| Idayamitha yangaphandle(mm) | 220±25 | 220±25 | 220±25 | 220±25 | 220±25 |

| Isithuba(mm) | 20 | 20 | 20 | 20 | 20 |

| Ubungakanani bepore(mm) | 65 | 65 | 65 | 65 | 65 |

| Indawo engaphezulu (m2/m3) | 118 | 128 | 135 | 132 | 148 |

| Umthamo wasimahla(%) | 85 | 75 | 72 | 75 | 73 |

| Uxinaniso olukhulu(kg/m3) | 280 | 320 | 340 | 300 | 348 |

Iingenelo zokusebenzisa iipakethe ze-ceramic ezilula zezi zilandelayo:

1. Imveliso ine-micropores ephuhliswe kakuhle kunye nekhono elinamandla lokubambelela kunye nokungcola kwe-adsorb; Ukugqithiswa kwerhasi ephezulu, iimicropores eziphuhliswe kakuhle, kunye namandla amahle. Ihlala ixesha elide ekuphathweni, impembelelo, kunye nokuhamba komoya. I-porosity yayo ebonakalayo yi-≥ 15%, kwaye inamandla okubambelela kunye ne-adsorption kwizinto ezahlukeneyo zokungcola kwigesi, ulwelo kunye nezinye iinkqubo zemidiya, kunye nesiphumo esihle sokucoca.

2. Ubunzima bemveliso yokukhanya, amandla aphezulu omatshini, kunye nokuchasana okuphantsi

Ubunzima bokupakishwa kwemveliso ye-ceramic filler ekhanyayo yi-280-350kg / m3, ephantsi kakhulu kunoxinaniso lwe-stacking yezizalisi eziqhelekileyo eziqhelekileyo. I-stacking porosity yemveliso ≥ 72%, i-porosity ebonakalayo yi-≥ 15%, kwaye i-porosity iyonke ingaphezulu kwe-85%. Imaski ineenzuzo zobunzima obulula, umthwalo omncinci, ukumelana nokusebenza okuphantsi, kunye noxinzelelo oluncitshisiweyo lwenqaba epakishwe.

Njengoko ukupakishwa okucwangcisiweyo, imveliso inokumelana nenqaba eyomileyo engaphantsi kwe-50mm ikholomu yamanzi kunye nokuxhatshazwa kokusebenza okungaphantsi kwe-100mm ikholomu yamanzi kwinqaba yokuhlamba i-naphthalene kunye ne-gas flux ye-50000 m3 / iyure, eyenza ukuba ingabikho ukuvaleka kwaye inqobe ukungahambi kakuhle kwe-breakage elula kunye nokuvalwa kwe-filling fillers.

3. I-coefficient yokudlulisa ubunzima obukhulu, indawo enkulu esebenzayo, kunye nesiphumo esihle sokwahlula

Umlinganiselo wokusebenza kwe-ceramic fillers ekhanyayo yiYunivesithi yaseTianjin ibonisa ukuba imveliso ine-coefficient yokudlulisa ubunzima obukhulu, okuyi-2.2 amaxesha kwezinye izizaliso. Ukongezelela, emva kokuba i-ceramic filler ekhanyayo izaliswe, kuphela imilenze ye-6 yenkxaso esondeleneyo idibanisa ukwenza indawo engasebenziyo, kwaye ukuhanjiswa kwe-gas-liquid kwifom yoqhagamshelwano "lobuso". Ukongeza, i-ceramic filler ekhanyayo yi-honeycomb microporous ceramic kunye ne-microporous area kunye ne-spatial droplet area, eyenza indawo esebenzayo yokuzalisa ibe mkhulu kune-99.5%, okubangela ukwahlukana kunye nemiphumo yokucoca.

4. Iifilisi ze-ceramic ezikhanyayo zinokumelana nokuguga okuqinileyo, ukuxhathisa ukubola, kunye nobomi benkonzo ende

I-ceramic filler ekhanyayo inokumelana nokushisa okulungileyo, kunye nokumelana nomlilo ukuya kwi-1400 ℃, kwaye iyamelana nokupholisa ngokukhawuleza kunye nokufudumeza; Ukongeza, umngxuma osixhenxe ogcweleyo we-ceramic oqhelekileyo une-asidi egqwesileyo kunye nokumelana ne-alkali, ubomi obude benkonzo, kwaye ayikuthandi ukuguga.

5. Yonke i-ceramic filler inesakhiwo senoveli, inokunqunyulwa, kwaye kulula ukuyizalisa

Uluhlu lwe-ceramic filler olukhanyayo oluqhelekileyo lunokunqunyulwa kwaye ludityaniswe kwisangqa, esingenakulungeleka kuphela ukuzaliswa, kodwa sivumela ukuba kusetyenziswe yonke indiza yokuzalisa. Ezinye izihluzi eziqhelekileyo, ngenxa yendalo yazo yokungasikwa, ngokungenakuthintelwa zinezithuba zobukhulu obahlukeneyo ezijikeleze inqaba, ezikhokelela kudonga olunzima kunye neziganeko zokuqukuqela komsele, ezinokuchaphazela ukusebenza ngempumelelo kokusetyenziswa ngokwemigangatho eyahlukeneyo.

Isishwankathelo, ukupakishwa kwe-ceramic yokukhanya kuye kwasombulula ngempumelelo ukuchasana phakathi kwe-porosity kunye nommandla othile wendawo, okungekho lula ukuvimba inqaba kodwa kunye nokusebenza kakuhle, okwenza kube yinto ekhethiweyo yabasebenzisi be-tower tower.