2022-07-29

1. Ukusebenza kokuhlukana kokupakishwa okucwangcisiweyo kuphezulu, kwaye izinga lokukhutshwa kwenqaba yokulungiswa liphezulu. Amazinga okukhutshwa kwe-oksijeni kunye ne-nitrogen yezixhobo zokwahlula umoya zihlukaniswe zibe zimbini iintlobo: izinga lokukhutshwa kwesethi epheleleyo yezixhobo kunye nesantya sokukhutshwa kwenqaba yokulungiswa. Ngenxa yesantya sokukhutshwa kwesethi epheleleyo yezixhobo kunye nomthamo wezixhobo zokwahlula umoya . Imveliso yeemveliso zolwelo inxulumene nezinye izinto. Kunzima ukulinganisa ukusebenza kakuhle kokuhlukana okuphezulu kokupakisha okucwangcisiweyo. Isantya sokutsalwa kwekholamu yokulungiswa kunye nesantya sokutsalwa kwe-argon sinokumela kangcono inqanaba loyilo lwesityalo sokuhlukanisa umoya. isixhobo esingaphantsi. Isantya sokutsalwa kweoksijini kwinqaba yayo yokulungisa ifikelele ngaphezu kwe-99%; izinga lokutsalwa kwe-argon lifikelele kwi-79%.

Ixabiso lokusebenza lomxholo we-oksijini kwi-nitrogen yamanzi amdaka kwinqaba ephezulu iyona nto isalathiso sesantya sokukhutshwa kokulungiswa kunye nokukhutshwa. Umlinganiselo wangempela ubonisa ukuba umxholo we-oksijini kwi-nitrogen yogutyulo unokuba ngaphantsi kwe-0.1%, kwaye ude ufikelele kwi-150-200x10-4%.

Ikholamu ephezulu yokupakishwa okucwangcisiweyo kunye nekholamu ye-argon ekrwada inomsebenzi ophezulu wokuhlukana, okusisiphumo sokunciphisa kakhulu uxinzelelo lwabo lokusebenza. Ukunciphisa uxinzelelo lokusebenza, ngakumbi ukwahlukana kwe-oksijini, i-nitrogen kunye ne-argon, kunye nokuhlukana kwe-oksijini kunye ne-argon. . Ngokuqhelekileyo, izinga lokutsalwa kwe-oksijeni linganyuswa nge-1% ukuya kwi-3%; izinga lokutsalwa kwe-argon linganyuswa nge-5% ukuya kwi-10%.

Isantya sokutsalwa kwenqaba yokulungiswa kwakhona sixhomekeke kumlinganiselo omkhulu kumlinganiselo womoya owandisiweyo ongena kwinqaba ephezulu, enempembelelo enkulu kwisantya sokutsalwa kwe-argon. Ke ngoko, ukusebenza kakuhle kwe-isentropic ye-turboexpander kunye ne-booster ratio ye-booster iyanda ngokuqhubekayo. , isitshixo sokunyusa izinga lokukhutshwa kwekholamu ye-distillation.

2. Ukungabikho kokupakishwa okucwangcisiweyo kukhulu, umthamo wemveliso mkhulu, kwaye ububanzi benqaba buyancitshiswa ukuze kube lula ukuthuthwa.

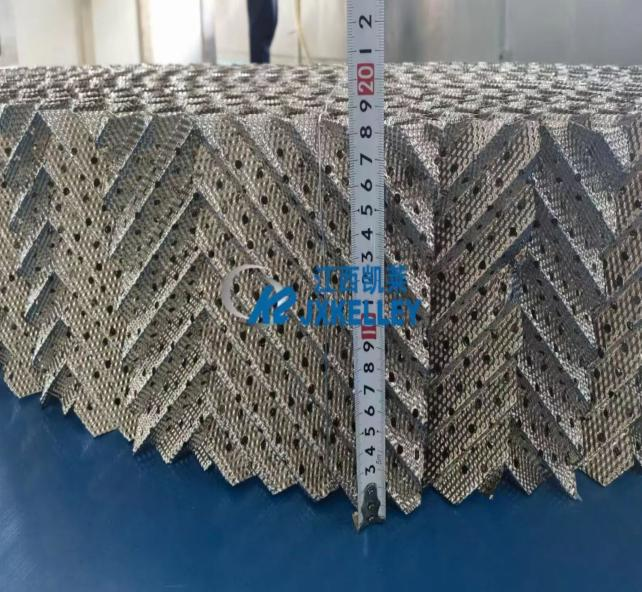

I-porosity yokupakisha okucwangcisiweyo ingafikelela ngaphezu kwe-95%. Kwikholamu yeplate ye-sieve, indawo yeplate ye-orifice ibalelwa malunga ne-80% yecandelo lomnqamlezo wekholamu, kwaye izinga lokuvula limalunga ne-8 ukuya kwi-12%, elingaphantsi kakhulu kunesantya sokuhla komoya somgangatho wokupakisha. Ngomthwalo ofanayo, umlinganiselo wekholomu yobubanzi bekholamu epakishweyo Inqaba ye-sieve ye-tray encinci; ngokubanzi, indawo yayo ye-cross-sectional kuphela ~ 70% ye-sieve tray tower, eyinzuzo ekuthuthweni kwezityalo ezinkulu zokwahlula umoya.

3. Ukupakishwa okucwangcisiweyo kunomthamo omncinci wokubamba ulwelo, umlinganiselo omkhulu wokusebenza kwe-fluid-to-gas kunye ne-elasticity, kunye neemeko zokusebenza eziguqukayo ngokukhawuleza.

Umthwalo osebenzayo we-sieve tray towers ukhawulelwe kukuvuza kwe-sieve kunye nesantya sokukhukula kwamanzi, ngelixa iinqaba ezipakishweyo zilinganiselwe kuphela ngesantya sokukhukula kwamanzi, ngoko ke imithwalo yabo yokusebenza inokwahluka phakathi koluhlu olubanzi, kwaye uluhlu lomthwalo woyilo lweenqaba ezipakishweyo lunokufikelela kwi-40% ukuya kwi-120%, ukuphuma kwe-oksijini kwinqaba ephezulu ye-3m ye-3m yokupakisha umoya we-3m ye-1200 yokupakishwa kwesityalo se-Shanghai I-Iron and Steel No.

Ngenxa yokubamba ulwelo oluncinci kwinqaba epakishiweyo, ngokuqhelekileyo yi-1% ukuya kwi-6% kuphela yomthamo wenqaba, ngelixa ukugcinwa kolwelo kwi-sieve tray tower yi-8% ukuya kwi-N% yomthamo wenqaba. Ixesha lokuhlala lifutshane kwaye ukuhla kwengcinezelo yokusebenza kuncinci, okukwanceda ekusebenzeni kweemeko zokusebenza eziguquguqukayo, kodwa kufuneka kuqinisekiswe ekusebenzeni kwangempela kweemeko zokusebenza eziguquguqukayo kwixesha elizayo.

4. Ixesha lokuqalisa isixhobo lifutshane kakhulu

Inkqubo yokuqalisa isityalo sokuhlukanisa umoya ayikho imveliso yokuphuma kwemveliso, ngoko ke ukunciphisa ixesha lokuqalisa yenye yeendlela zokuthi isityalo sokuhlukanisa umoya sigcine amandla nokunciphisa ilahleko. Emva kokusebenzisa ukupakisha okukhoyo okucwangcisiweyo, ubuninzi be-liquid obubambayo ngexesha lokulungiswa okuqhelekileyo luyancipha kakhulu, olunciphisa kakhulu ixesha lokuqalisa kwesityalo sokuhlukanisa umoya.

Ixesha lokuposa: Aug-01-2022