I-RTO-UTshintsho loBusi kwiCeramic yeCeramic

Imisebenzi

1.Nciphisa ilahleko ye-thermal yokukhupha igesi, kunye nokuphucula ukusebenza kakuhle kwamafutha ukugcina amandla njengoko.

2.Ukuphucula ukushisa okutshisayo okusekelwe kwi-theory, ukuphucula ukutshisa kwe-atmospheric, ukuhlangabezana nokushisa okuphezulu kwezixhobo ze-thermal ukwandisa ixabiso le-calorific ixabiso eliphantsi, ngokukodwa uluhlu lwesicelo se-furnaces yokuqhuma, ukuphucula ukusebenza kakuhle kwexabiso le-calorific ixabiso kunye nokunciphisa ukukhutshwa kwegesi yamalahle exabiso eliphantsi le-calorific.

3.Ukuphucula imimiselo yokutshintshiselana kobushushu kwiziko, ukwandisa imveliso yezixhobo, ukuphucula umgangatho weemveliso kunye nokunciphisa ukutyalomali kwakhona kwizixhobo.

4.Nciphisa ukukhutshwa kwezixhobo ze-thermal, ukunciphisa ukungcola komoya kunye nokuphucula indawo.

Iimpawu

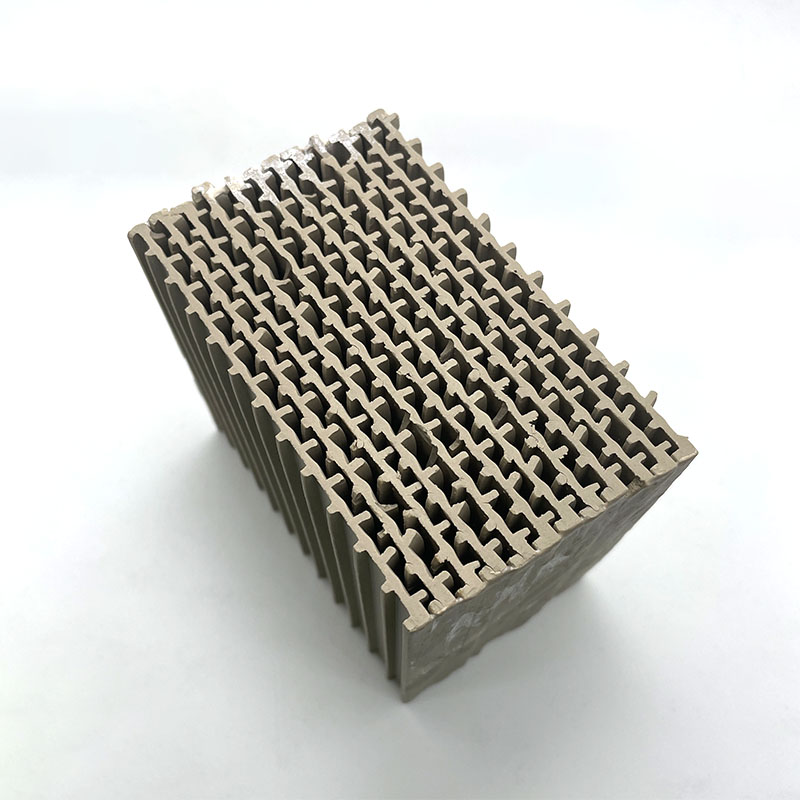

Iimpawu ze-honeycomb ze-ceramic regenerator zimi ngolu hlobo lulandelayo: banokwandiswa kobushushu obuphantsi, amandla aphezulu obushushu obuthile, indawo ethile ephezulu, ukuhla koxinzelelo oluphantsi, ukuchasana kwe-thermal, ukuhanjiswa kakuhle kwe-thermal, ukunyanzeliswa kwe-thermal kunye nokunye okuninzi. Ke, kumashishini esinyithi kunye neekhemikhali, isetyenziswa njenge-HTAC, ngelixa sidibanisa ukuphinda kusetyenziswe ubushushu bokukhutshwa, ukutsha okuphezulu okusebenzayo kunye nokunciphisa i-NOx. Iba yinto egcina amandla okwenene kwaye iyancipha iNox.

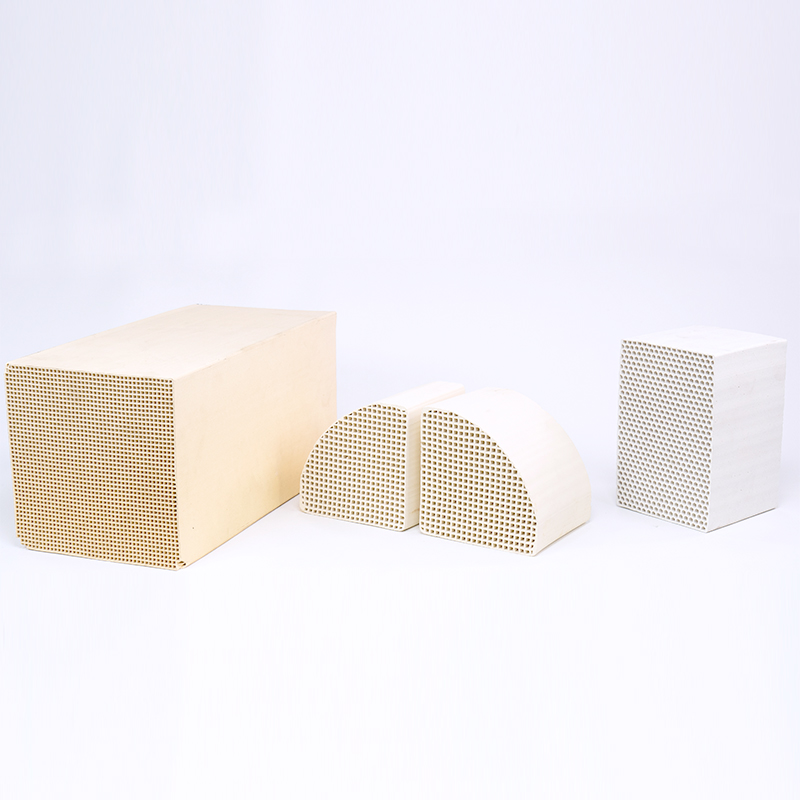

Izixhobo: iAlumina, iAlumina exineneyo, iCordierite, iCordierite exineneyo, iMullite, iCorundum Mullite kunye nabanye

Isicelo

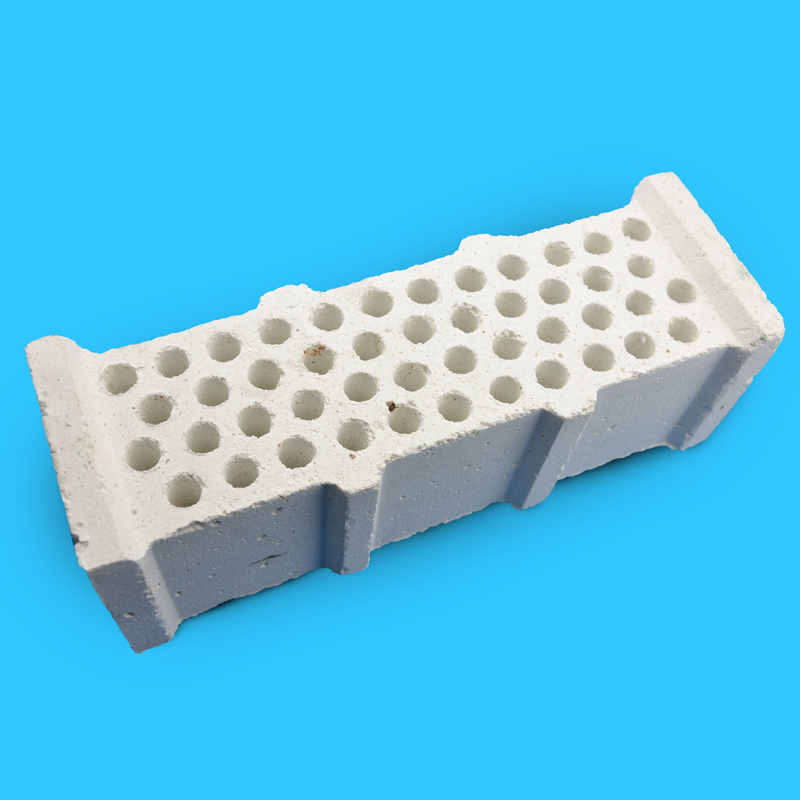

I-ceramic ye-honeycomb ingundoqo kunye necandelo eliphambili lokugcina ubushushu obuphezulu beteknoloji yokutshisa ukushisa (iteknoloji ye-HTAC). Isetyenziswe ngokubanzi kwiindawo ezahlukeneyo zokufudumeza intsimbi, ukuhamba kwezixhobo zokufudumeza, iziko lokunyanga ubushushu, ukubumba iziko, iziko lokunyibilikisa, i-ladle / i-tundish roasters, izitofu zokuntywila, izitofu zetyhubhu ezikhazimlayo, kunye neziko lohlobo lwentsimbi kumashishini oomatshini besinyithi. Isithando somlilo, isithando somlilo esivuthayo; amaziko ahlukeneyo e-ceramic kunye neentlobo ezahlukeneyo zeglasi kwishishini lezinto zokwakha; iindawo ezahlukeneyo zokufudumeza i-tubular, iziko eliqhekezayo kunye nezinye iziko loshishino kwishishini lepetrochemical.

Iinkcukacha

100x100x100, 100x150x150, 150x150x150, 150x150x300mm kunye nabanye

Ukubalwa komngxuma: 25x25, 40x40, 43x43, 50x50, 60x60 kunye nabanye

Ubungakanani

| Ubungakanani (mm) | Iiseli (N×N) | Ukuxinana kweeSeli (CPSI) | Ububanzi beSitishi (mm) | Udonga lwangaphakathi Ukutyeba (mm) | Free Cross Section (%) |

| 150×150×300 | 20×20 | 11 | 6.00 | 1.35 | 64 |

| 150×150×300 | 25×25 | 18 | 4.90 | 1.00 | 67 |

| 150×150×300 | 32×32 | 33 | 3.70 | 0.90 | 63 |

| 150×150×300 | 40×40 | 46 | 3.00 | 0.70 | 64 |

| 150×150×300 | 43×43 | 50 | 2.80 | 0.65 | 64 |

| 150×150×300 | 50×50 | 72 | 2.40 | 0.60 | 61 |

| 150×150×300 | 59×59 | 100 | 2.10 | 0.43 | 68 |

Ukuqulunqwa kwemichiza

| Into | Cordierite | Mullite | Alumina Porcelain | I-Alumina ephezulu yePorcelain | Corundum |

| Al2O3 | 33 | 65 | 54 | 67 | 72 |

| SiO2 | 58 | 30 | 39 | 23 | 22 |

| MgO | 7.5 | <1 | 3.3 | 1.7 | <1 |

| Abanye | 1.5 | 14 | 3.7 | 8.3 | 5 |

Iipropati Zomzimba

| Into | Cordierite (Inabile) | Mullite | Alumina Porcelain | I-Alumina ephezulu yePorcelain | Corundum | |

| Ubuninzi (g/cm3) | 1.8 | 2.0 | 1.9 | 2.2 | 2.5 | |

| Ukufunxwa kwamanzi (%) | 23 | 18 | 20 | 13 | 12 | |

| I-Coefficient yoKwandiswa kweThermal(×10-6K-1) (20~800℃) | ≤3.0 | ≤6.0 | ≤6.3 | ≤6.0 | ≤8.0 | |

| Ubushushu obuthile (J/Kg.K) (20~1000℃) | 750-900 | 1100-1300 | 850-1100 | 1000-1300 | 1300-1400 | |

| I-Thermal Conductivity (W/mk) (20~1000℃) | 1.3-1.5 | 1.5-2.3 | 1.0-2.0 | 1.5-2.3 | 5~10 | |

| Max. Ubushushu bokusebenza.(℃) | 1200 | 1400 | 1300 | 1400 | 1650 | |

| Amandla okutyumza kweAxial (MPa) | Yomile | ≥11 | ≥20 | ≥11 | ≥22 | ≥25 |

| Ukuntywiliselwa | ≥2.5 | ≥2.5 | ≥2.5 | ≥2.5 | ≥2.5 | |